Coating faults - when upgrading wooden doors using our Fire Retardant Varnish or Fire Paint

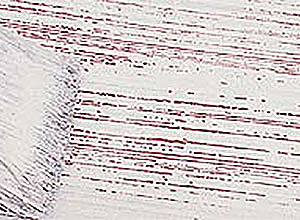

Coatings fail to spread evenly whilst being applied and then dries in streaks or circles - called Cissing and Dimpling - or form depressions as they dry.

Cissing appears during coating and goes through to the previous coating layer or wood

Dimpling appears during coating,

but does not go through to the previous coating layer or the wood

Craters appear in the coating as it dries - not usually obvious during coating

and do not go through to the previous coating layer or the wood

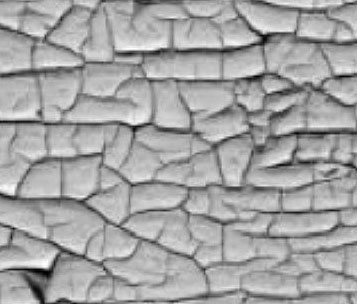

Mud cracking forms as the product shrinks during drying or curing - lots of uneven cracks form

These faults can be avoided by carrying out a number of simple tests.

Fault Types

Cissing and dimpling are very small circular defects, where the paint or varnish has receded to expose the base coating or bare wood.

If the central base coat or wood area is visible, the defect is known as 'cissing'.

If the central base coat or wood is not visible the defect is known as a 'dimple'.

These faults are usually around 1-3mm in diameter and are visible straight after application, well before the coating starts to dry.

Causes of cissing and dimples

1. Water repellence in the surface from previous coatings of paint, wax, oil or wood treatments

2. Coating over gloss finishes or oil based paints

3. Coating over chemical residues from chemical stripping

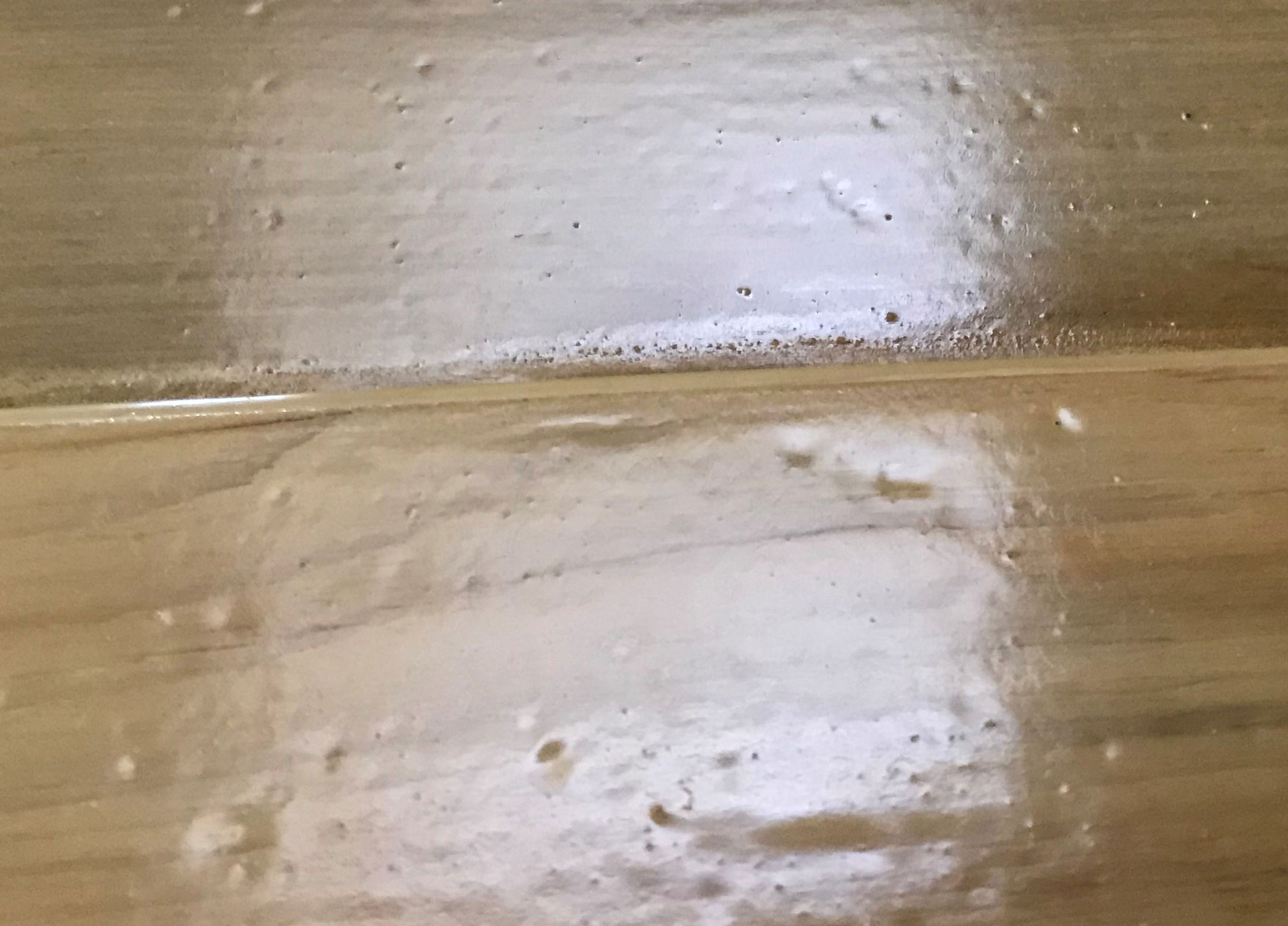

Craters are visible in the form of small bowl shaped depressions

in the paint film.

Do not confuse these with cissing/dimpling because the causes are different.

Causes of Craters

1. Air bubbles in the coating due to poor mixing technique - always power mix using a paddle, slowly.

2. Chemical reaction between the surface and the coating that causes gas bubbles to form and puncture after the product has started to set

Mud cracking slowly becomes visible during drying and curing as the product shrinks

Causes of Mud Cracking

1. Excessive product thickness

2. Chemical reaction between the surface and the coating that causes a lack of adhesion

3. Over-rapid drying out, usually due to high ambient temperatures

Surfaces to avoid

Fire Varnish - do not attempt to varnish over unprepared existing varnish, wax, stain, paint, lacquer or water repellant treatments.

Do not varnish over freshly stripped doors or panels without checking the moisture content and the PH (acidity) of the surfaces - aim for Neutral at 7, or less, to ensure a slightly acidic surface. Litmus results above 7 indicate an alkaline surface - do not proceed without prior washing and neutralisation using vinegar.

Fire Paints - although less sensitive to surface problems than Fire Varnish, best not to attempt to paint over unprepared existing varnish, wax, stain, gloss paint, lacquer or water repellant treatments.

Do not paint over freshly stripped doors or panels without checking the moisture content and the PH (acidity) of the surfaces - aim for Neutral at 7, or less, to ensure a slightly acidic surface. Litmus results above 7 indicate an alkaline surface - do not proceed without prior washing and neutralisation using vinegar.

Initial Preparation and workspace environment

Sand down all surfaces to a matt finish and remove all dust. Maintain an even temperature and humidity during coatings, particularly over night, to avoid possible condensation issues.

If you are intending to use Fire Varnish ensure that the work space is isolated from the rest of an occupied building and well ventilated.

The Intumescent Fire Varnish gives of a strong odour and a vapour during the drying period, until it is over coated (when hard) with the Flame Finish Varnish.

Pre Product Testing

1. Test random areas of the prepared wood surfaces, using single drops of water (from a spoon or syringe), to assess the degree of water repellence.

If the water drops flatten and spread immediately the surfaces are suitable for an Emulsion Test.

2. Apply small patches of normal Emulsion Paint to random small patches to test for 'cissing'.

If the paint lays flat and dries flat, with no circular defects or streaks, you are ready for a Product Test.

3. Product tests should then be carried out on a non important test sample area to ensure that the finish and colour of the base intumescent coat and the finish coat are acceptable, before proceeding with full coating.

If in doubt send us photographs and call us on 01626 872 886.

Stripped Doors and Panels - a special case

Doors and panels that have been stripped using chemicals may still have chemical and paint/varnish residues on the surfaces. These contaminants can cause:

1. Sissing - gaps in the paint or varnish film where the surface has repelled the coating - these gaps go right through the fresh coating, down to the previous coat or bare surface

2. Dimples - hollow spots where during the drying out process the contaminants have reacted with the coating - these are depressions and do not go down to the previous coat or bare surface

To reduce the risk of such defects check the prepared surfaces in random spots by applying small drops of water and testing with Litmus Paper. The Litmus Paper must give a Neutral (7) or slightly Acidic (6) result for it to be safe to proceed with the application of Intumescent Fire Varnish.

If the result shows a residual Alkaline colour (8+) on the Litmus Test treat the surfaces with a coat of White Vinegar and when that is fully dried re-test. If the result is still Alkaline purchase some of our Salt Neutraliser - click here to see Salt Neutraliser

Speak to us now for door upgrade free help and immediate pricing - Tel: 01626 872886

Fast UK Delivery of all Fire Door upgrading Varnishes - Price Matching Offer

Click here to look at the product, check prices and Order in our Fire Paint Shop

Fire Door Clear Varnishes I Fire Door Finish Paint I Loft Conversion Fire Doors

Returns Policy I Privacy Policy I Contact us

Other Property Repair Systems Sites:

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.epoxy-info.co.uk - epoxy resins for repairing wood, concrete, brick and stone

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.propertyrepairsystems.co.uk - our Home Site

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber.org.uk - systems of repair, with step by step methods

www.timber-repair.co.uk - how to repair timber beams